24

2022

-

12

Refractory materials for the heat storage chamber of glass kilns - silica bricks

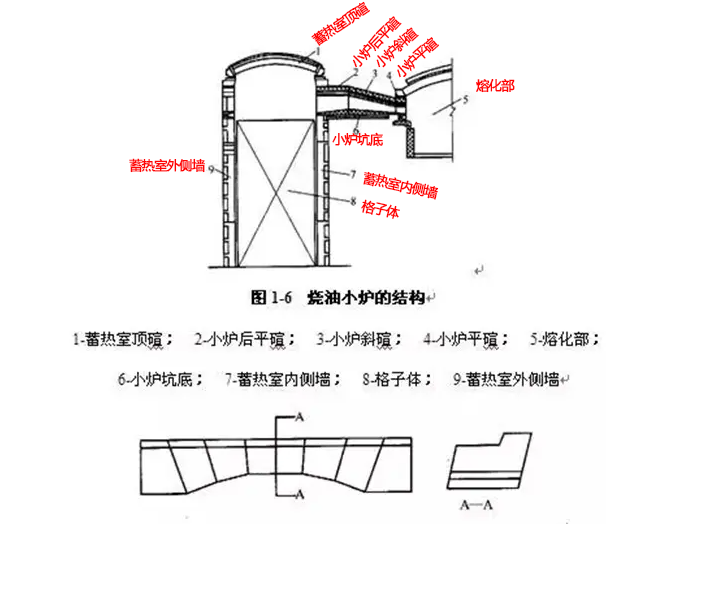

The main function of the heat storage chamber as a waste heat recovery equipment of the kiln is to preheat the air to a sufficiently high temperature. The heat storage capacity of the heat storage chamber depends on the heat transfer area of the lattice body.

The main function of the heat storage chamber as a waste heat recovery equipment of the kiln is to preheat the air to a sufficiently high temperature. The heat storage capacity of the heat storage chamber depends on the heat transfer area of the lattice body. A sufficiently large heat transfer area can effectively increase the temperature of the preheated air and reduce the discharge temperature of the flue gas. To ensure sufficient heat transfer area, the length, width and height dimensions of the heat storage chamber should become larger, and the one-time investment of bricks increases. To a 1250t / d glass furnace for example, the upper wall such as the use of magnesium bricks amounted to 1265t, such as all replaced by silica bricks for 865t, the material cost of only 25% of the magnesium bricks, investment reduction is obvious. Therefore, in order to reduce investment costs, the upper wall of the heat storage room using silica bricks began to increase.

Properties of silica bricks

Silicon bricks for glass melting kilns have the following properties.

i. High temperature volume stability, will not cause changes in the furnace body due to temperature fluctuations. Due to the high load softening temperature and small creep rate of silica bricks, the glass kiln can keep the furnace body at 1600℃ without deformation and stable structure.

ii. No pollution to the glass liquid. The main component of silica brick is SiO2, and it does not affect the quality of glass liquor if it drops or molten drops on the surface when it is used.

iii. Chemical erosion resistance. The upper structure of the silicon brick by the glass ingredients containing R2O gas erosion, the surface of a smooth layer of metamorphic layer, so that the rate of erosion becomes low, to play a protective role.

iv. Small bulk density. Can reduce the mass of the furnace body.

Related News

Henan YUANDONGLI Refractory Technology Co., Ltd.

Service Hotline:+86-371-8580-0003

Address: No. 9, Rengou Group, Magou Village, Laiji Town, Xinmi City, Zhengzhou City, Henan Province, China