24

2022

-

12

Measures on how to extend the age of glass kiln

refractory materials: the quality of refractory materials in all parts of the kiln must be ensured, the refractory materials in different parts should be properly matched, the parts that need to do acid and alkali separation must be separated by reliable materials, the refractory materials in contact with the glass liquid must be able to resist glass liquid erosion and scouring, the lattice body materials in the heat storage chamber and the upper section should be resistant to high temperature and alkaline dust erosion.

1, refractory materials: the quality of refractory materials in all parts of the kiln must be ensured, the refractory materials in different parts should be properly matched, the parts that need to do acid and alkali separation must be separated by reliable materials, the refractory materials in contact with the glass liquid must be able to resist glass liquid erosion and scouring, the lattice body materials in the heat storage chamber and the upper section should be resistant to high temperature and alkaline dust erosion.

2, the steel structure of the kiln: for example, a 500t / d level of float glass kiln is made of nearly twenty different varieties of refractory materials, more than three hundred size specifications, hundreds of thousands of pieces (500 to 700,000 pieces), a total weight of several thousand tons (5,000 to 8,000 tons) of refractory masonry. The steel structure of the kiln is used to support and restrain the brick structure of the masonry. The steel structure of the kiln must ensure that the brick structure of each part of the kiln can be maintained without deformation or crushing of the bricks from the beginning of the masonry to the high temperature operation after the expansion. Therefore, the steel structure of each part of the kiln that is not weak and not too strong.

3, expansion joints: the kiln structure of the glass melting kiln to operate at high temperatures for a long time, the expansion joints in various parts of the kiln have a great impact on the age of the kiln. Refractory materials have thermal expansion, to ensure the safety of the kiln structure, some parts of the kiln structure subject to expansion restrictions must be left with appropriate expansion joints to ensure that the refractory bricks are not crushed at high temperatures and the kiln wall is not deformed.

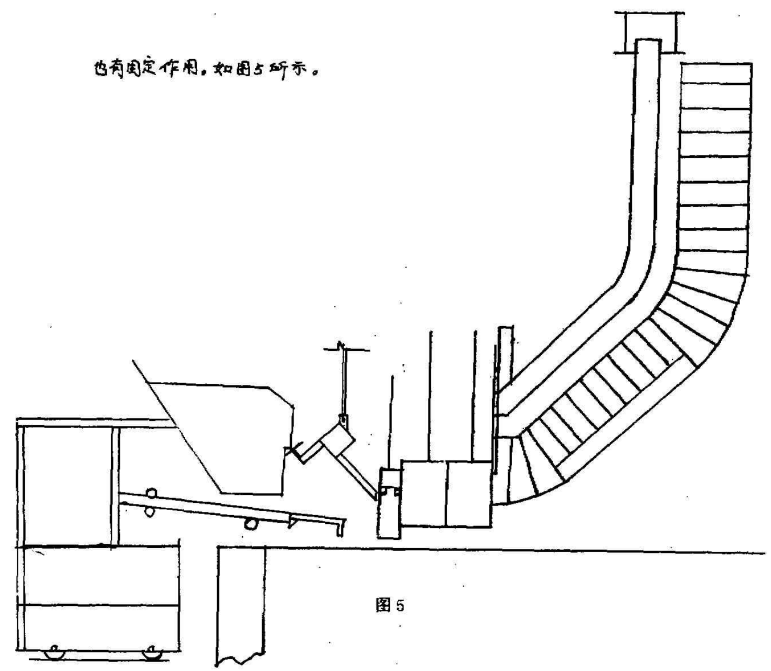

L-shaped hanging wall: In the past, the front face wall of the glass kiln generally used silica bricks to make the "fish-belly swan" structure. Fish maw swan strand span ratio is generally small, calculated fish maw swan swan brick compressive stress are relatively large; fish maw swan silicon brick is acidic materials, to withstand the chemical erosion of alkali steam within the compound material; fish maw swan brick also has to withstand the high temperature effect of heat erosion and erosion. Fish belly swan in such poor working conditions, safety and reliability is very poor, once is one of the weak links affecting the life of glass kiln. In response to the short service life of fish belly swan, L-type hanging wall structure was developed. With the application of L-shaped hanging wall structure in the front face of glass kiln, the safety and reliability problem of the front face wall structure of the kiln has been well solved.

The L-hanging wall structure is safe and has a long service life, which is one of the essential measures to extend the life of the whole kiln. The distance between the lower edge of the wall and the top surface of the pool wall is small, so that a thinner layer of material can be fed to facilitate the melting of the mating material; the flying material at the head of the kiln can be reduced, thus saving energy and improving the environment. The service life is more than 10 years.

5、Kiln pressure: The kiln pressure in the melting section is usually 5-7 Pa, which means that the pressure inside the kiln is 5-7 Pa higher than the pressure outside the kiln, and the micro-positive pressure inside the kiln is to ensure that the cold air outside the kiln enters the kiln less and that the kiln wears less fire outside the kiln. The greater the kiln pressure, the more likely it is to wear fire outside the kiln, making some small gaps should not wear fire, due to wear fire and become a large seam, which is commonly known as "burn through", burn through the life of the kiln structure will have an impact.

6、Air-cooling and water-cooling: The places where the glass kiln needs to be cooled by blowing air mainly include: the pool walls on both sides of the melting section, the pool walls on both sides of the card neck, the swan foot beam in the melting area, the feeding port stop iron, L-shaped hanging wall, etc. The places where water cooling is needed mainly include: the outer corner of the pool wall at the entrance of the neck, the outer corner of the pool wall at the intersection of the liquid level pool and the melting section, etc.

7, kiln masonry: the quality of glass kiln masonry plays a big role in the life of the kiln, you must choose a qualified professional construction unit, construction equipment to complete, supporting the type of work, quality supervision is indispensable, there are detailed masonry requirements for each part of the glass kiln, must be guaranteed.

8, baking kiln temperature rise: baking kiln temperature rise is crucial to the operating life of the glass kiln, it will irreversibly affect the performance and life of the kiln later. For example, due to improper kiln baking caused by the deformation of the kiln body, cracking, sinking, squeezing, etc., are to affect the age of the kiln. Baking kiln heating curve must be reasonable, and the parts of the temperature rise that need to control expansion must be operated in a timely and accurate manner and strictly controlled.

9, reasonable operation: the temperature regime of the glass melting kiln should be reasonable, the kiln pressure in all parts should be reasonable and stable, the liquid level fluctuations should be small, various facilities in good condition, accurate operation, and do not produce damage to the kiln body during operation.

Maintenance: To do daily inspection of the kiln body according to the operating procedures of the glass melting kiln, and carry out timely maintenance when problems arise. In the middle and late stages of kiln operation, we should strengthen the maintenance work.

Related News

Henan YUANDONGLI Refractory Technology Co., Ltd.

Service Hotline:+86-371-8580-0003

Address: No. 9, Rengou Group, Magou Village, Laiji Town, Xinmi City, Zhengzhou City, Henan Province, China